WELCOME TO Luker Chocolate

We are a family business with more than 110 years of experience. We develop fine chocolates and cocoa crafted at origin, with exceptional taste and purpose. In our effort to drive wellness throughout the cocoa value chain, we partner with brands and companies committed to quality and sustainability.

CHOCOLATE PORTFOLIO

As a high quality chocolate manufacturer our products are made exclusively from directly sourced Cacao Fino de Aroma and are characterised for their superior taste and diversity. Our portfolio includes both finished products and chocolate ingredients. Ethically sourced and developed for the wellbeing of consumers, farmers and the environment.

CHOCOLATE AS AN INGREDIENT

All of our chocolate ingredients guarantee a unique flavor that is given by the pureness of its origins. Carefully selected beans from different Cacao Fino de Aroma growing regions. Its flavor does reflect not only the cocoa variety but also the richness of the soil and the growing culture of its regions.

KNOW MORE

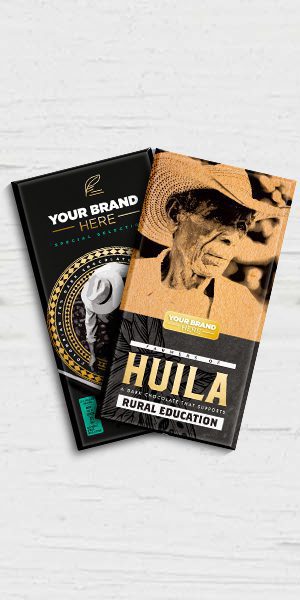

PRIVATE LABEL CHOCOLATES

From chocolate bars to healthy chocolate snacks, Luker Chocolate can help you formulate, manufacture and design high-quality chocolate products for your customers. All with our Cacao Fino de Aroma signature taste.

KNOW MORE

WE GO BEYOND SUSTAINABILITY

The Chocolate Dream is a collaborative model of social innovation, in which Luker Chocolate seeks to transform the chocolate value chain from origin. This builds sustainable well-being amongst the communities where Luker Chocolate sources its cocoas.

WE ARE PRESENT IN THE WHOLE COCOA VALUE CHAIN

SOURCING

PROCESSING

MOULDING

PACKAGING

Recommended Posts for you

Uses & Opportunities of Caramel Chocolate Couverture for Product Development

Caramel and chocolate are a match made in heaven and for a good reason. The perfect combination for an indulgent treat.

A step-by-step guide to developing a new chocolate product

Explore our step-by-step guide to chocolate product development. Learn how Luker Chocolate brings your unique chocolate ideas to life.

A Look at the Hottest Flavours in Chocolate Confectionery in 2024

We are thrilled to share the latest innovations from our research and development department. Get ready to indulge in all things confectionery.